-

CNC Turning Parts: Understanding the Basics

CNC turning is a process of machining that uses computer-controlled cutting tools to remove material from a rotating workpiece. The process is used to create precise and complex parts for a wide range of applications. CNC turning parts are commonly used in the aerospace, automotive, medical, and manufacturing industries, among others. In this article, we will discuss the basics of CNC turning parts, including what they are, how they are made, and their applications.

What are CNC Turning Parts?

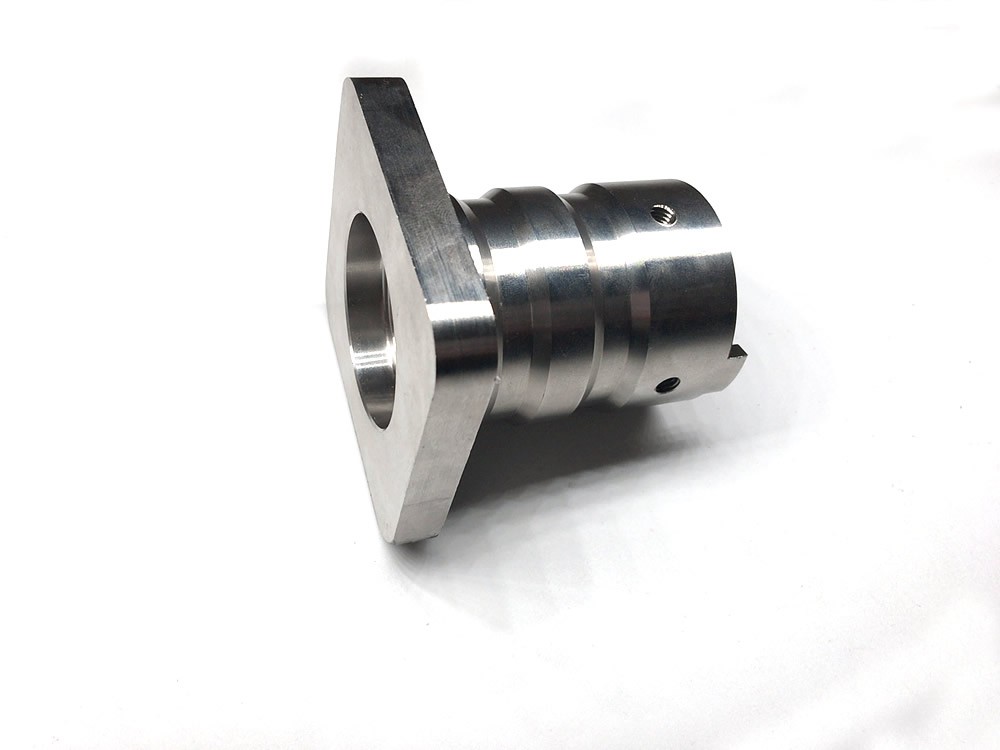

CNC turning parts are parts that are machined using a CNC lathe, which is a type of machine tool that rotates a work piece while a cutting tool removes material from the work piece. CNC turning parts can be made from a wide range of materials, including metal, plastic, and wood. The process is used to create a variety of parts, including shafts, bushings, connectors, and more.

How are CNC Turning Parts Made?

CNC turning parts are made using a CNC lathe, which is programmed with a set of instructions that tell the machine how to move the cutting tool and rotate the workpiece. The cutting tool is mounted on a tool turret, which can hold multiple cutting tools, allowing for a variety of machining operations to be performed without the need for manual tool changes.

The workpiece is mounted in a chuck or collet, which holds the workpiece securely in place while it rotates. As the workpiece rotates, the cutting tool moves along the surface of the workpiece, removing material to create the desired shape and size.

Applications of CNC Turning Parts

CNC turning parts are used in a wide range of applications, from simple components to complex assemblies. Some common applications of CNC turning parts include:

1. Aerospace: CNC turned parts are used to create components for aircraft engines, landing gear, and other critical systems.

2. Automotive: CNC turning parts are used to create engine components, suspension systems, and other critical components.

3. Medical: CNC turning parts are used to create surgical instruments, medical devices, and other critical components for the healthcare industry.

4. Manufacturing: CNC turning parts are used to create a wide range of components for industrial machinery, including gears, bearings, and more.

Conclusion

CNC turning parts are an essential component of modern manufacturing processes. With the ability to create precise and complex parts, CNC turning has revolutionized the way that parts are manufactured, making it possible to create parts that were once thought to be impossible. Whether you are in the aerospace, automotive, medical, or manufacturing industry, CNC turning parts can help you create the high-quality parts you need to succeed.

-

CNC Turning Parts: Understanding the Basics of CNC Turned Parts

CNC turning parts are essential components in the manufacturing industry. They are used in various applications, including automotive, aerospace, medical, and electronics. CNC turned parts are made using computer numerical control (CNC) machines that can create intricate shapes and designs. In this article, we will discuss the basics of CNC turned parts, their applications, and the benefits of using them in manufacturing.

What are CNC Turned Parts?

CNC turned parts are components that are created using a CNC lathe machine. These machines use computer-aided design (CAD) software to create precise cuts and shapes on a variety of materials, including metal, plastic, and wood. CNC turned parts can be customized to fit specific applications, and they are known for their accuracy, consistency, and reliability.

Applications of CNC Turned Parts

CNC turned parts have numerous applications in various industries. In the automotive industry, they are used to create engine parts, brake components, and suspension systems. In the aerospace industry, CNC turned parts are used to create critical components like landing gear, hydraulic systems, and engine parts. In the medical industry, CNC turned parts are used to create surgical instruments and medical implants. In the electronics industry, they are used to create components like connectors, sensors, and switches.

Benefits of Using CNC Turned Parts

CNC turned parts offer several benefits over traditional manufacturing methods. One of the main advantages is their accuracy and consistency. CNC machines can create complex shapes and designs with a high degree of precision, ensuring that each part is identical. This level of precision reduces the risk of errors and defects, improving the overall quality of the final product.

Another advantage of using CNC turned parts is their speed and efficiency. CNC machines can create parts at a much faster rate than traditional manufacturing methods, reducing production time and costs. They can also run continuously, which means that they can create large quantities of parts with minimal human intervention.

CNC turned parts are also very versatile. They can be made from a variety of materials, including metals, plastics, and wood. This means that they can be used in a wide range of applications and industries.

Conclusion

CNC turning parts are an essential component of modern manufacturing. They offer numerous benefits over traditional manufacturing methods, including accuracy, consistency, speed, efficiency, and versatility. CNC turned parts are used in various industries, including automotive, aerospace, medical, and electronics. As technology continues to advance, CNC machines are becoming more advanced, allowing for even greater precision and efficiency.

-

Revolutionize Your Manufacturing Process with CNC Turning Parts

CNC turning parts, also known as CNC turned parts or simply turned parts, are a crucial component in precision manufacturing. These parts are manufactured using a specialized process called CNC turning, which involves cutting, drilling, and shaping metal or other materials with a high degree of precision and accuracy.

CNC turning parts are widely used in various industries, including aerospace, automotive, medical, and industrial manufacturing. They are used to produce a variety of components, including shafts, pins, screws, valves, and more. CNC turning parts offer several advantages over traditional manufacturing methods, including increased accuracy, repeatability, and faster turnaround times.

The CNC Turning Process

CNC turning is a complex manufacturing process that involves the use of computer-controlled machines to cut and shape metal or other materials. The process starts with a solid block or bar of raw material, which is secured in a chuck and rotated at high speed. The cutting tool, which is controlled by a computer program, then moves along the material, removing excess material to create the desired shape and size.

The CNC turning process can produce parts with extremely tight tolerances and complex geometries. The use of computer-controlled machines ensures that each part is identical, which is crucial in many industries that require precision and consistency.

Advantages of CNC Turning Parts

CNC turning parts offer several advantages over traditional manufacturing methods. First and foremost, CNC turning parts offer increased accuracy and repeatability. The computer-controlled machines ensure that each part is identical, which is crucial in industries that require precision and consistency.

Second, CNC turning parts can be produced much faster than traditional manufacturing methods. This is because the process is automated, which reduces the need for manual labor and speeds up the production process.

Finally, CNC turning parts can be produced in a wide variety of materials, including metals, plastics, and composites. This versatility allows manufacturers to create parts that are tailored to the specific needs of their industry.

Conclusion

CNC turning parts are a crucial component in precision manufacturing. They are used in a wide variety of industries to produce complex components with tight tolerances and high accuracy. The CNC turning process offers several advantages over traditional manufacturing methods, including increased accuracy, repeatability, and faster turnaround times. As technology continues to evolve, it is likely that CNC turning parts will become even more prevalent in precision manufacturing.

-

Precision Engineered CNC Turning Parts: Optimizing Your Manufacturing Processes

CNC turning is a machining process that involves using computer-controlled machines to shape metal or plastic components. CNC turning parts are an essential component of modern manufacturing processes, and they are used in a wide range of industries, including automotive, aerospace, medical, and electronics.CNC turning parts are produced using a lathe, which rotates the workpiece while a cutting tool removes material from it. The cutting tool is controlled by a computer program, which allows for precise control of the machining process. This precision makes CNC turned parts highly accurate and ensures that they meet exact specifications.

One of the benefits of CNC turning parts is that they can be produced in large quantities with high consistency. This is because the CNC machines can run continuously, producing identical parts each time. This is especially useful in industries that require a high volume of parts, as it allows for more efficient production and lower costs.CNC turning parts can be made from a variety of materials, including steel, aluminum, brass, and plastic. The choice of material will depend on the specific application of the part, as well as the requirements for strength, durability, and corrosion resistance.The CNC turning process is highly versatile, and it can be used to create a wide range of components, from simple bolts and fasteners to complex components with intricate geometries. This makes CNC turning parts ideal for a variety of applications, including engine components, hydraulic systems, and electrical connectors.

CNC turning parts can also be customized to meet specific requirements. This can include adding features such as grooves, threads, and chamfers, as well as custom finishes such as anodizing, powder coating, or painting. This customization allows for greater flexibility in design and ensures that the part meets the exact needs of the application.

CNC turning parts are also highly efficient. The precision and accuracy of the machining process means that there is minimal waste, which reduces costs and ensures that the manufacturing process is more environmentally friendly. Additionally, the use of computer-controlled machines means that the machining process can be optimized to reduce cycle times, further reducing costs and increasing efficiency.

In conclusion, CNC turning parts are an essential component of modern manufacturing processes. They offer high precision, accuracy, and consistency, and can be customized to meet specific requirements. With the ability to produce large quantities of parts efficiently and with minimal waste, CNC turning parts are an essential tool for a wide range of industries.

-

Pick the best collecting association to buy the Steel Machined Parts

Machine parts are seen everywhere and thereafter it will be quite easy to see. Clearly, CNC machining is sensible and strong for the extent of metals and plastics. Also, the machine parts are easily made quickly and tolerably, and no tooling is required. With the master bunch, you could get machined parts and models at fair costs in the short lead terms. The experts could have more data in this field and work with various regions. Steel Machined Parts are seen out of control, from microscopic metal to engine plane parts, as a great many things are made with the aide of the machining framework.

Lately, the most stunning and custom machine parts are involved CNC machines. It will in general be metal or plastic, then, it will make from the material, and a while later it might be cut without certainly performing. Thusly significantly more parts are machined ensuing to being worked with another gathering cooperation. Consequently, you truly need more bits of knowledge in regards to the parts, and a while later you ought to keep scrutinizing the article and obtaining information.

Why do you have to use the steel machine parts?

There are various inspirations driving why much more regions are using machined parts. This is the explanation appreciating various advantages to Steel Parts. First and foremost, it could have brilliant strength, and a short time later it will work from areas of strength for the of material and subsequently be manufactured in various thicknesses and shapes. Moreover, it will have contrastingly featured, and a short time later it might be created utilizing various materials. As such, the lesser measures of machined parts will be made quickly, which may not require tooling. Furthermore, it protections will be especially close if the machining speed is diminished. Since much more associations are using it, this is the explanation machining is endeavoured and had a go at gathering strategy.

Along these lines, the steel machined parts will most likely satisfy the associations' rules and testament. It will devise various benefits, so try to get it from a trustworthy collecting association. It will give excellent benefits to people so consider it and gain the benefits. Right when you need to buy the things, you ought to consider a faithful collecting association and a short time later buy the extraordinary things for various purposes. It will be an incredible part and a while later give the uncommon benefits with basically no more issues subsequently consider it and thereafter gain the benefits.

-

Critical Arrangement Considerations for CNC Turned Parts

CNC turning is a metal production process wherein a segment is held set up on a turning shaft which interfaces with a proper gadget to kill material until the part is in its optimal shape.

In CNC turning parts, the work piece turns around the cutting gadget to make exactness parts. CNC turned parts can be used in different organizations, from vehicle to flying. A large part of the time, they are used to make parts that are pretty much nothing or delicate to be made by other gathering methodologies. Due to the serious degree of accuracy and repeatability, CNC-turned parts are a large part of the time used in fundamental applications where dissatisfaction is certainly not a decision.

With respect to these parts, plan thoughts are essential to the result of the finished thing. This article will analyze five of the most fundamental arrangement thoughts for CNC-turned parts.

1) Material assurance

The material you use for a CNC-turned part can profoundly impact the general arrangement. For example, metals like aluminium and metal are sensitive and moldable, simplifying them to machine. In any case, they moreover will by and large be solid areas for less solid than harder materials like steel or titanium.

2) Obstruction

CNC (PC numerical controlled) machines are used to make turned parts with an uncommonly serious degree of precision. The machines are changed with comply to a lot of rules that let them in on the most proficient method to cut and shape the material. This cycle ensures that each part is exactly the same as the one going before it, which is essential for precision planning applications.

In CNC turning, the work piece turns around the cutting gadget to make precision parts. CNC-turned parts can be used in different endeavours, from auto to aeronautics. When in doubt, they are used to make parts that are close to nothing or delicate to be made by other gathering methods. In light of the serious degree of precision and repeatability, CNC-turned parts are a large part of the time used in essential applications where disillusionment is definitely not a decision.

With respect to these parts, plan considerations are essential to the result of the finished thing. This article will analyze five of the most basic arrangement considerations for CNC-turned parts.

1) Material decision

The material you use for a CNC-turned part can fundamentally impact the general arrangement. For example, metals like aluminium and metal are fragile and bendable, simplifying them to machine. Regardless, they moreover will frequently be solid areas for less intense than harder materials like steel or titanium. To make the best choice, it is critical to contemplate the application and needed properties of the part, as well as the particular capacities of the CNC turning process.

The CNC machining material ought to be adequately ready to get through the powers of machining, but it moreover ought to be heat-safe and wear-safe. Likewise, the material ought to be reasonable with the coolant and lubes that will be used during the machining framework. Failure to pick the right material can provoke part disillusionment, excessive fixes, and even injuries.

2) Versatility

In any CNC turning part plan, certain mysterious risks can ceaselessly cause the part to be out-of-obstruction. The clarifications behind these risks can be various and changed, yet every now and again they can be followed back to the arrangement of the genuine part. To restrict the bet of issues occurring, it is key that the organizer gives due thought to the issue of machining strength in their arrangement.

3) Surface finishing

While considering the arrangement of a CNC Turned Part, surface finishing is a huge part to consider. Achieving the ideal surface fruition can be a test, and some unsatisfactory choice of material or tooling can provoke sad results.

4) Stringing and scoring

While arranging a precision CNC-turned part, it is basic to consider the most well-known approach to hanging and scoring. Hanging gives a strategy for getting two pieces together by interlocking them, while scoring thinks about a smooth advancement between two surfaces.