When it comes to precision engineering and manufacturing, metal stamping parts take center stage. These versatile components play a pivotal role in various industries, and their importance cannot be overstated. In this article, we delve into the world of metal stamping, exploring its significance, applications, and the factors that make it a cornerstone of modern manufacturing.

The Art of Metal Stamping

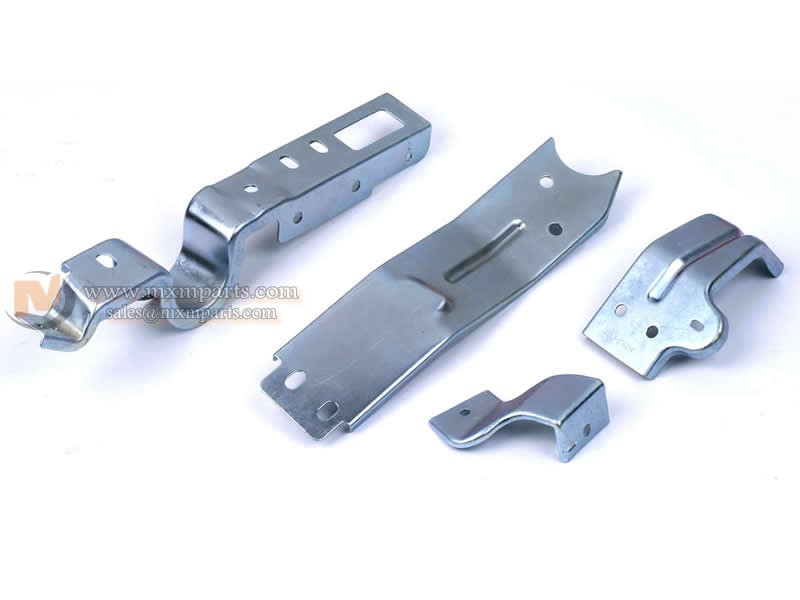

Metal stamping, often referred to as pressing, is a manufacturing process that involves shaping, cutting, or forming metal sheets into desired shapes and sizes. This process utilizes a combination of dies and stamping presses, ensuring high precision and repeatability in producing intricate metal components.

The Applications Are Endless

Automotive Industry

In the automotive sector, metal stamping parts are the unsung heroes that contribute to the structural integrity and aesthetic appeal of vehicles. From body panels to engine components, these parts are vital for creating safe and efficient automobiles.

Electronics and Appliances

In the world of electronics and appliances, metal stamping parts find their place in circuit boards, heat sinks, and enclosures. Their durability and thermal conductivity make them ideal for ensuring the reliability of electronic devices.

Aerospace Engineering

In the aerospace industry, where precision and performance are non-negotiable, metal stamping parts are used in critical applications. They find their way into aircraft components, ensuring safety and efficiency at 30,000 feet.

Medical Equipment

When it comes to life-saving medical equipment, precision and reliability are paramount. Metal stamping parts are employed in manufacturing medical devices, guaranteeing the highest quality and performance standards.

Key Benefits of Metal Stamping

Precision and Consistency

Metal stamping offers unparalleled precision and consistency, making it a preferred choice for industries where tight tolerances are essential.

Cost-Efficiency

The high-speed nature of metal stamping processes ensures a cost-efficient production method, saving both time and money.

Material Versatility

From stainless steel to aluminum, metal stamping can be applied to a wide range of materials, providing flexibility in design and functionality.

The Role of Innovation

As technology advances, the world of metal stamping is not left behind. Innovations such as computer-aided design (CAD) and advanced die materials have elevated the capabilities of metal stamping parts to new heights. This continual evolution ensures that metal stamping remains a cornerstone of manufacturing excellence.

Conclusion

In conclusion, metal stamping parts are the unsung heroes of the manufacturing world, shaping industries and propelling progress. Their precision, versatility, and cost-efficiency make them indispensable in various applications, from automobiles to aerospace. As innovation continues to push the boundaries of what's possible, the role of metal stamping parts in shaping our future is undeniable. So, the next time you see a car on the road or a medical device in action, remember the silent contribution of metal stamping in making it all possible.