The automobile industry comes with a collection of spare parts for various machines. Using high-quality spare parts will make the function long and safer way. So many high-quality machine parts are required to build and function the heavy machines.

Machine parts functions:

In this case, the machinery parts are made up of different metals, even plastic martial; depending on the needs and the requirements, the machinery parts can be purchased by the experts. For heavy machinery and industrial purposes, Steel Machined Parts are the best choice to fix in the machines for better function and for long life.

This gives more advantages and makes the function more effective; getting g the machined parts in the best manufacturing place will let upon know the specification increase manner to use them with guaranty

Use g a piece of high-quality machinery is easy to maintain, and stainless steel is a Successful machined part for heavy operations. Using the best quality machine parts will strengthen the solid brocks of materials and make the operation thicknesses.

Advantages of machined parts:

Machined parts offer certain benefits. The injection molded parts and 3D printed parts using in a wide range of operations.

1. No MOQ

2. 2. Good prototypes

3. Designed freedom

4. Quality

5. Lead times

6. Alterations

7. Strength

8. Surface finish

The machined parts can be made with different metals. Depending on the industry, the materials can be used, and some machinery needs very soft materials; in some cases, the materials need a shallow milling point. Here common, some of the machined parts Martials such as Metal, plastic, as machined, bead blasted, anodized, powder coated using the stainless steel machinery part gives corrosion resistance, scale resistance, and acid resistance. Furthermore, 100% recyclable features provide the station with less steel and environmentally friendly materials.

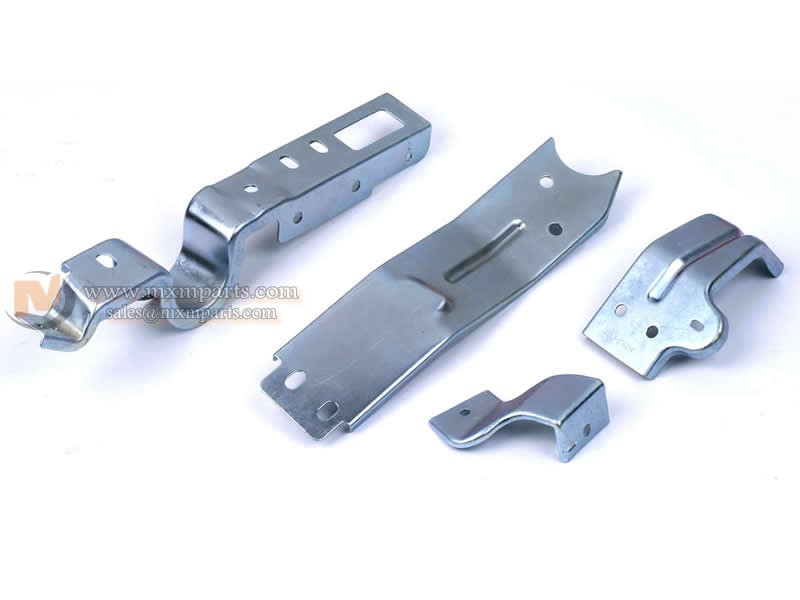

Stamping process:

Another way the manufacturing industry does Metal Stamping Parts. Metal stamping comes in three components of metal stamping they are sheet metal, die and press machine. Turning the metal sheet into a functional part is known as metal stamping. The stamping process is the die work that creates shapes in the sheets. Without heat, the sheet metal stamping dies the sheet in excellent cooling formation techniques. During the metal stamping, some processes occur: Forming, blanking, drawing, piercing getting the Metal. Stamping, the leading company, will provide high-quality materials. These are the materials used for heavy machinery in the industry.